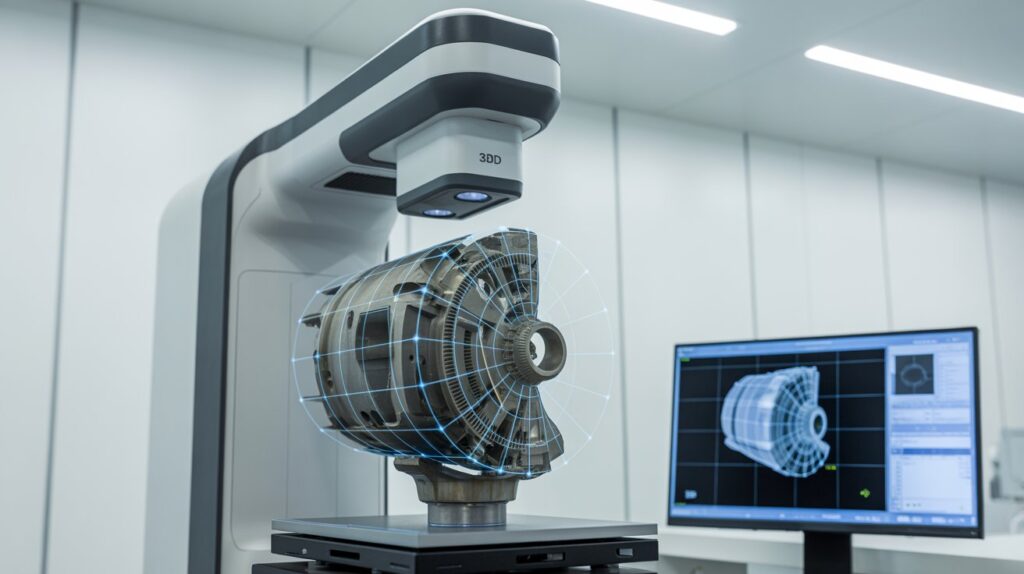

India’s Trusted Partner for Industrial-Grade 3D Scanning company

Professional 3D Scanning Services in India

Scan any part, any size, anywhere with precision you can rely on

Book a call With Expert

About 3D Paradise: Accurate and Reliable Industrial-Grade 3D Digitization

At 3D Paradise, we deliver 3D scanning services in India that help businesses convert physical parts and assets into accurate digital data. Our work supports manufacturers, engineers, designers, and institutions involved in reverse engineering, dimensional inspection, digital documentation, and manufacturing processes.

All scanning is performed by trained technicians using calibrated, industrial-grade equipment and defined engineering workflows. Each project is reviewed for accuracy requirements, data security, and intended application, whether the scope involves a small precision component or a large industrial structure.

What We Do

We provide end-to-end 3D scanner services that convert real-world objects into usable digital data.

Capture accurate 3D data from existing parts for redesign, modification, or replication.

High-precision inspection and quality control using calibrated 3D scanning systems.

Secure digital documentation of components, tools, and industrial assets.

Clean, validated scan data prepared for CNC machining and additive manufacturing.

Accuracy requirements up to 30 microns are handled by trained technicians using calibrated equipment.

Trusted High-Quality 3D Scanning in India at Affordable Prices

3D scanning in India are commonly used for reverse engineering, dimensional inspection, and digital documentation of physical parts. Using established scanning methods, accurate surface and measurement data is captured to support design, analysis, and manufacturing workflows.

Service scope

3D scanning for engineering use: Data capture for CAD comparison, inspection, and redesign

Multiple scanning approaches: Suitable for small components, complex geometries, and large parts

Cost-controlled scanning projects: Pricing aligned with part size, accuracy needs, and data output

Engineering-reviewed results: Scan data prepared for practical use, not just raw point clouds

India-wide service coverage: Standardized processes followed across locations

The service focuses on accuracy, process consistency, and usable digital output for technical applications.

Our 3D Scanning Capabilities

We select scanning technology based on part size, surface complexity, and final application requirements.

Handheld Laser Scanning

Ideal for medium to large components, tooling, molds, and onsite scanning inside factory environments.

Structured Light Scanning

Used for small to medium parts that require high surface detail, fine geometry capture, and tight accuracy.

Large-Scale LiDAR Scanning

Suitable for buildings, industrial plants, aircraft, and large assemblies where complete spatial capture is required.

Portable CMM Scanning

Best suited for metrology-grade inspection, dimensional validation, and tolerance-critical measurements.

Proven results delivered through professional 3D scanning, inspection, and digital measurement services for engineering and industrial projects across India.

A clear, structured workflow to ensure accurate 3D scanning results, from initial review to final data delivery.

We review your part, accuracy requirements, and intended application to define the most suitable scanning approach.

Certified technicians perform 3D scanning using the most appropriate technology for the part and environment.

Scan data is cleaned, aligned, and processed into usable formats while maintaining accuracy and data integrity.

You receive validated files in the required formats, securely delivered and ready for engineering or manufacturing use.

Our 3D scanning in India support engineering, inspection, and documentation use cases where accuracy, validation, and reliable digital data are required.

Accurate 3D scanning of legacy or undocumented components to recover geometry, support part reproduction, and enable manufacturing continuity.

Scan-based dimensional inspection used to verify geometry, tolerances, and form against reference CAD data before production approval.

Surface and dimensional inspection of tools, dies, and molds to identify wear, deformation, and deviations affecting production quality.

Conversion of processed scan data into accurate CAD models for design updates, CNC machining, and engineering documentation.

Preparation of clean, watertight scan data suitable for additive manufacturing and rapid prototyping applications.

High-resolution 3D documentation of heritage objects, industrial assets, and large structures for preservation and long-term reference.

Why Choose Our 3D Scanning Services

We focus on accuracy, clarity, and reliable delivery, providing dependable results without overpromising.

Service Coverage Across India

We provide professional 3D scanning services across major industrial regions through onsite and lab-based support.

and additional locations supported by mobile onsite teams.

- Point cloud data and watertight mesh files

- CAD models in STEP or IGES format

- Inspection and deviation reports

- Files ready for manufacturing or documentation

File formats and data outputs are selected based on how the scanned data will be used in your engineering or documentation workflow.

3D scanning costs are determined after a technical review and depend on the following factors:

- Part size and geometric complexity

- Accuracy and inspection requirements

- Post-processing and engineering effort required

If you need accurate and dependable 3D scanning services in India, our team is ready to support your engineering and inspection requirements.

Our 3D scanning services in India support industries that rely on accurate digital data for inspection, engineering, and documentation.

Each project is executed using industry-specific standards, validated workflows, and appropriate handling procedures to ensure accuracy and data integrity.

3D Printing in Education

For schools, colleges, and training institutes looking for hands-on learning through real working models and STEM tools.

3D Printing for Healthcare

For medical practitioners needing anatomical models, surgical guides, and patient-specific components with high accuracy.

3D Printing for the Jewelry Sector

Ideal for designers creating intricate patterns and casting-ready masters with exceptional detail and finish.

3D Printing for Artistic Design

For artists transforming digital concepts into sculptures, installations, and decorative pieces with premium finishing.

3D Printing for the Automotive Sector

Supporting automotive R&D with durable prototypes, test-fit parts, and lightweight production components.

3D Printing for Medical Uses

Advanced medical components for labs, clinics, and hospitals requiring fast, reliable, functional polymer or resin parts.

3D Printing for Prototyping

For startups and engineering teams needing fast, accurate prototypes for form, fit, and function testing.

3D Printing for Robotics

Precision parts for grippers, end effectors, drone components, housings, and functional mechanisms.

Industries We Serve

What Our Clients Say

Rated ★★★★★ on Google by 80+ happy customers for our quality, service, and reliability.

EXCELLENTTrustindex verifies that the original source of the review is Google. Helped us design and manufacture a new product. Supportive staff and high quality services.Trustindex verifies that the original source of the review is Google. NiceTrustindex verifies that the original source of the review is Google. 2 year'sTrustindex verifies that the original source of the review is Google. Unser Unternehmen in Deutschland wandte sich an 3D Paradise für die Entwicklung neuer Produkte und kundenspezifischer Lösungen für den europäischen Markt. Das Unternehmen 3D Paradise mit Sitz in Delhi setzte unsere Ideen und Konzepte in ergonomisches 3D-Cad-Design um und realisierte einen Prototyp für uns, der jetzt ein hervorragendes Produkt auf dem europäischen Markt ist. 3D Paradise bietet wirklich schnelle, kosteneffiziente und qualitative Lösungen für Ihre Ideen und Designs. Dieses Unternehmen hat die Kompetenz, Ihre Probleme zu lösen und Ihre Konzepte und Ideen in reale Produkte umzusetzen. Wir sind sehr zufrieden mit dem Engagement von 3D Paradise und streben eine lange, fruchtbare Geschäftsbeziehung an.

Common Questions

FAQ'S

Reverse engineering is the process of converting a physical part into an editable CAD model using high-accuracy 3D scanning when original design data is unavailable.

No. Reverse engineering is specifically used when CAD files, drawings, or documentation do not exist or are outdated.

You receive editable CAD files such as STEP, IGES, or native CAD formats, suitable for CNC machining or further design work.

Yes. The output CAD models are validated and prepared for CNC machining, tooling, or production, based on defined accuracy requirements.

Accuracy depends on part size and method used, and can reach up to 30 microns for precision components.

Yes. Worn or partially damaged parts can be reverse engineered by reconstructing functional geometry and correcting wear-related deviations.

Yes. Onsite 3D scanning is available for large, heavy, or fixed components that cannot be transported to a lab.

Simple parts take 1–2 days, medium complexity parts 3–5 days, and complex assemblies 1–2 weeks, depending on scope.

Cost is determined by part size, geometry complexity, required accuracy, and the level of CAD reconstruction needed.

Yes. All projects are handled under strict confidentiality agreements with secure data storage and encrypted file transfer.

Clients We Serve