3D Printing in Delhi

Book a call With Expert

Top 3D Printing Service in Delhi

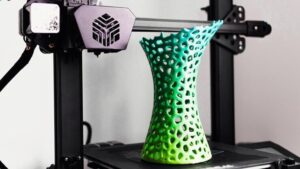

Looking for reliable 3D printing in Delhi? At 3D Paradise, we turn your concepts into reality with fast, affordable, and high-precision 3D printing services tailored for startups, students, engineers, architects, designers, and hobbyists. Whether you need functional prototypes, miniature models, custom tools, or artistic creations, we support every stage of your product journey—from idea to final print. Our cutting-edge technologies like FDM, SLA, and SLS ensure detailed, durable, and accurate results every time.

How 3D Printing Works

3D printing—also known as additive manufacturing—is the process of creating real, three-dimensional objects from a digital design. Instead of cutting or molding, this method builds objects layer by layer, using materials like plastic, resin, or even metal. It’s fast, cost-effective, and perfect for customized parts, prototypes, or one-of-a-kind designs.

At its core, the 3D printing process starts with a CAD file (Computer-Aided Design). This digital model is sliced into thin layers and sent to the printer. The machine then lays down material—layer by layer—until the object is complete. Different technologies like FDM, SLA, and SLS are used depending on the material, speed, and detail required.

A 3D model is made using CAD software or 3D scanning.

The model is sliced into digital layers using slicing software.

The printer reads each layer and builds the object from bottom to top.

Layers are cooled (FDM) or cured by UV light (SLA) to harden the structure.

Supports are removed, and finishing touches like polishing or painting are applied.

Advance 3D Printing Technologies (FDM, SLA, SLS)

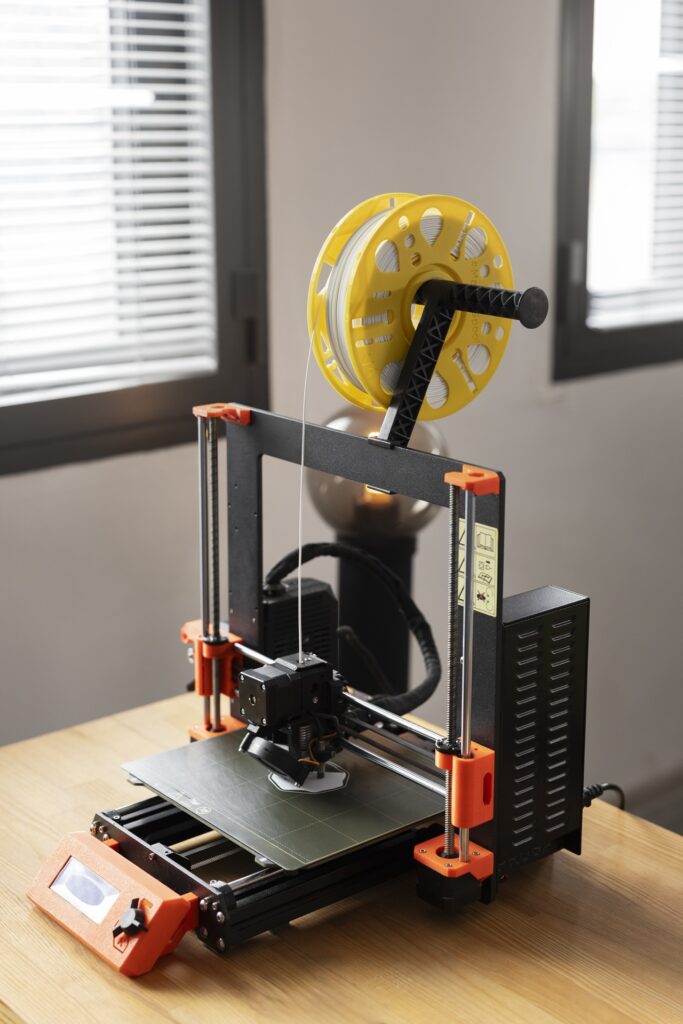

Fused Deposition Modeling (FDM)

FDM is one of the most used 3D printing technologies currently available. It works by melting thermoplastic filament and depositing it in thin layers with a hot nozzle, creating models from the bottom up.

- Affordable and rapid for everyday use

- Support materials such as PLA, ABS, PETG, Nylon, and TPU

- Suitable for both decorative and utilitarian models

- Parts engineering testing and prototyping

- Factory tools, jigs, and fixtures

- Low-volume production and special mechanical parts

Ideal for startups, students, and engineers who require working prototypes at a fraction of the cost of conventional methods.

Stereolithography (SLA)

SLA employs a high-precision UV laser to cure photosensitive liquid resin. This creates parts with a smoother surface finish and microscopic detail, a favorite among aesthetic and delicate applications.

- Offers high-definition detail and smooth surfaces

- Ideal for thin, small, or ornamental work

- Utilizes precision resin materials for precision

- Medical devices and dental molds

- Jewelry and collectible figurines

- Presentational or visual models.

Where surface detail and appearance are of primary importance, SLA is the 3D printing method of choice.

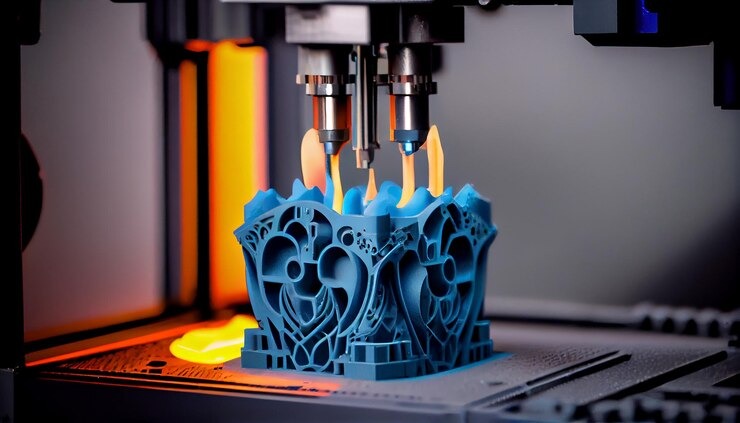

Selective Laser Sintering (SLS)

SLS employs a strong laser to bond powdered material (typically nylon) into solid material—no support structures required. Complex and interlocking parts can be created.

- Durable and heat-resistant parts

- Supports complex designs and mechanical fitments

- Uses powder-based materials

- Aerospace and automotive functional prototypes

- Living hinges and custom-fit connectors

- End-use materials and tools, wear-resistant

Engineers and manufacturers who need parts with complex geometry and industrial strength.

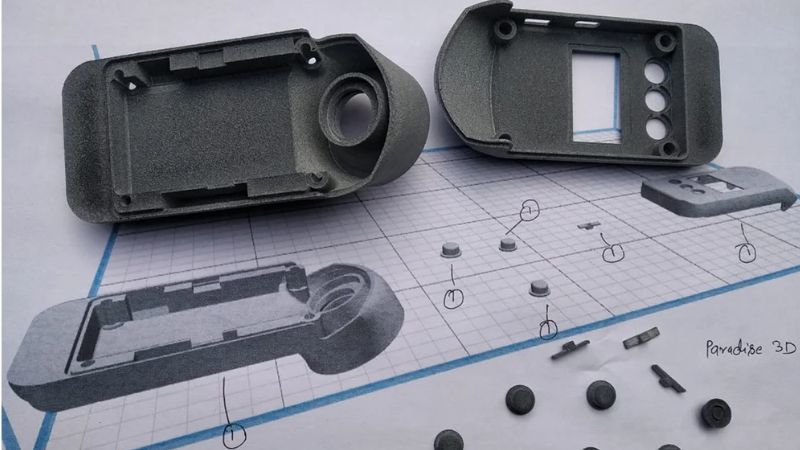

3D Design Services (CAD Modeling)

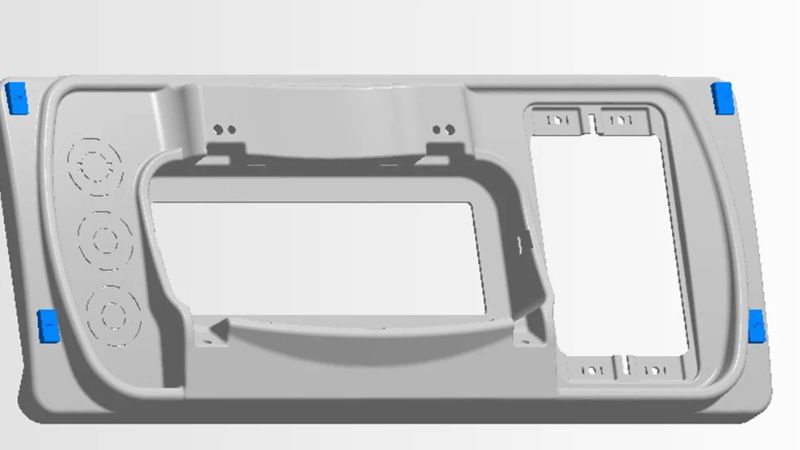

CAD (Computer-Aided Design) modeling is the process of creating precise digital 3D models using specialized software. These virtual designs serve as blueprints for 3D printing, product development, and digital simulation.

Highly detailed and dimensionally accurate designs

Editable digital files that can be optimized for manufacturing

Compatible with all major 3D printing technologies

Concept-to-prototype design development

Product visualization and simulation

Architecture, mechanical parts, medical devices, and consumer goods

Preparing STL files for 3D printing

Startups looking to create MVPs or product concepts

Engineers and product developers needing precise component models

Students working on academic or design projects

Architects and designers requiring custom layouts or scale models

Popular Industries Using 3D Printing Service in Delhi

The versatility of 3D printing in Delhi has made the technology ubiquitous in various industries. Some of the key sectors savoring the bounty of services offered by 3D Paradise are as follows.

Manufacturing and Prototyping

For manufacturers, rapid prototyping is the the convenience of 3D printing: it means that they can quickly test and iterate over product designs in a highly accelerated time-to-market approach. Lower lead times, improved product development, and reduced costs for traditional prototyping-these are just some of the benefits 3D Paradise offers manufacturers.

Healthcare and Medical Devices

3D printing transforms how medical devices are produced in the health sector, including personalized medical equipment, prosthetic limbs, and dental models. This software house offers medical-grade materials and high-precision printing so that healthcare providers can create specific solutions for their patients.

Education and Research

Delhi universities and research centres utilize 3D printing services to innovate and overhaul the learning process and take innovation to the next levels. For example, if anatomy-related topics are a subject of problem, then anatomical models can be designed. Similarly, if it is some engineering or experimental design-related issues, then prototypes can be executed there to work out solutions. Thus, all these are quite economical and reliable for educational purposes through 3D Paradise. The functionality 3D Paradise provides to architects and artists: 3D Paradise enables the most detailed models and sculptures to be created by architects and artists alike. In the hands of architects, 3D printing applies designs for buildings, while in the hands of artists, it is used to recreate very detailed, customized prints of creative ideas.

Want to create stunning 3D designs for your business? Let us be your partner

Popular Industries Using Best 3D Printing in Delhi

The versatility of Best 3D printing in Delhi has made the technology ubiquitous in various industries. Some of the key sectors savoring the bounty of services offered by 3D Paradise are as follows.

Manufacturing and Prototyping

For manufacturers, rapid prototyping is the the convenience of 3D printing: it means that they can quickly test and iterate over product designs in a highly accelerated time-to-market approach. Lower lead times, improved product development, and reduced costs for traditional prototyping-these are just some of the benefits 3D Paradise offers manufacturers.

Healthcare and Medical Devices

3D printing transforms how medical devices are produced in the health sector, including personalized medical equipment, prosthetic limbs, and dental models. This software house offers medical-grade materials and high-precision printing so that healthcare providers can create specific solutions for their patients.

Education and Research

Delhi universities and research centres utilize 3D Printing service Delhi to innovate and overhaul the learning process and take innovation to the next levels. For example, if anatomy-related topics are a subject of problem, then anatomical models can be designed. Similarly, if it is some engineering or experimental design-related issues, then prototypes can be executed there to work out solutions. Thus, all these are quite economical and reliable for educational purposes through 3D Paradise. The functionality 3D Paradise provides to architects and artists: 3D Paradise enables the most detailed models and sculptures to be created by architects and artists alike. In the hands of architects, 3D printing applies designs for buildings, while in the hands of artists, it is used to recreate very detailed, customized prints of creative ideas.

Our 3d print designs for different Industries