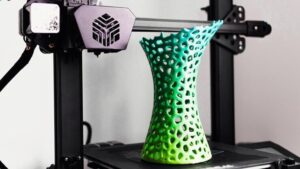

Turn your designs into reliable parts at Hyderabad Industrial 3D Printing facilities

Trusted 3D Printing Services in Hyderabad

From Your Idea to a Functional 3D Model

Supports STL, STEP, IGES, OBJ, 3MF, SolidWorks and Fusion 360

Book a call With Expert

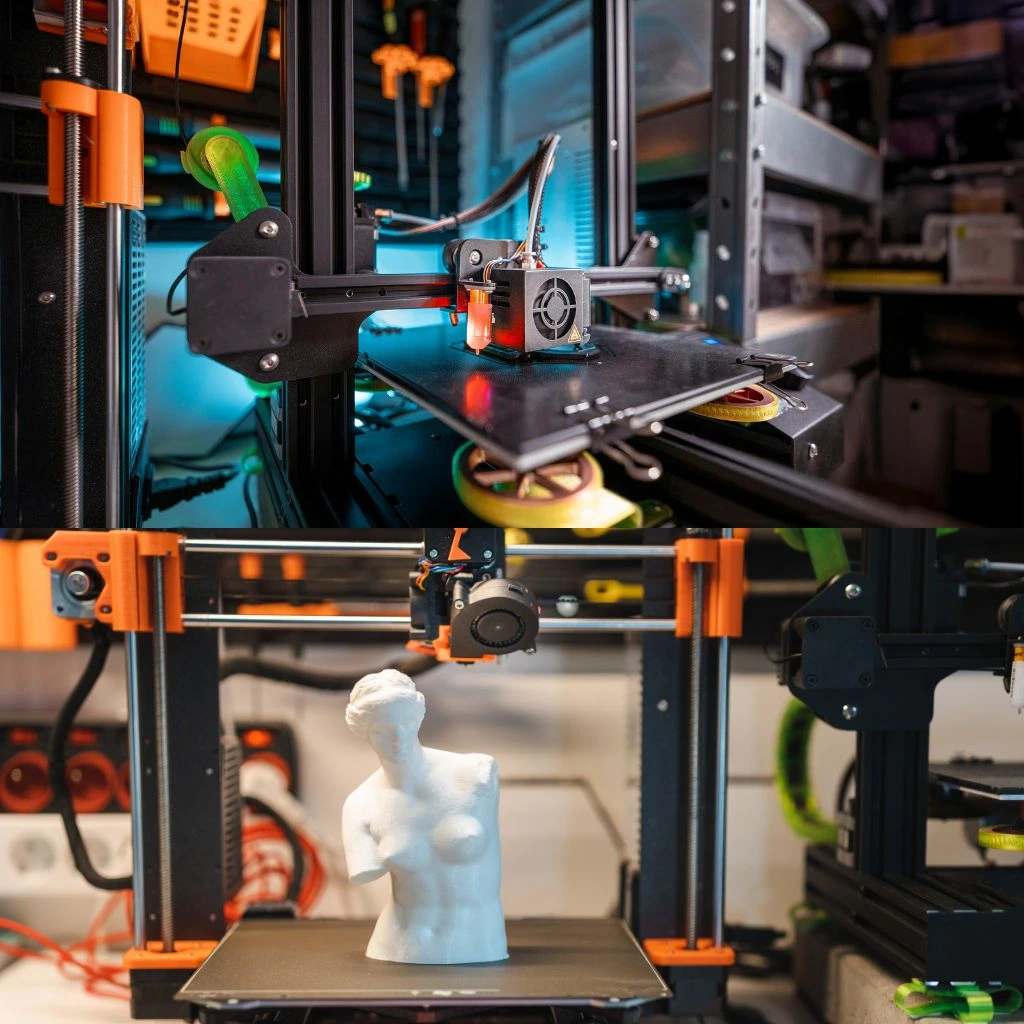

About 3D Paradise – Industrial 3D Printing in Hyderabad

3D Paradise Technology LLP provides industrial 3D printing services in Hyderabad for engineers, startups, manufacturers, and research teams that require accurate, functional, and production-ready parts. Our ISO-certified facility is located at T-HUB, Gachibowli, supporting prototyping, product development, and low-volume production.

We focus on performance-driven parts, not display models or showpieces. Every project begins with a clear understanding of the part’s end-use, followed by careful selection of the printing process and materials to ensure reliable, application-ready results.

Since 2016, we have supported projects across automotive, medical, aerospace, healthcare, Jewelry and Architecture manufacturing sectors. Our services include functional prototyping, design validation, and repeatable production using FDM, SLA, and SLS technologies.

Backed by a qualified engineering team and a structured production workflow, we help Hyderabad-based businesses move faster with dependable quality and predictable timelines.

Why Hyderabad Businesses Trust Us

No Minimum Order Quantity

Order a single part or scale to low-volume production with the same engineering accuracy and quality.

Transparent, Clear Pricing

Quotes are shared upfront with full clarity on material, process, and timelines. No hidden charges.

Local Engineering Team

Designs are reviewed by Hyderabad-based engineers who understand real manufacturing requirements.

Fast Local Turnaround

All parts are produced locally at our Gachibowli facility, reducing lead times and logistics delays.

Industrial-Grade Facility

ISO-certified processes with industrial SLS, SLA, and FDM systems ensure reliable, repeatable output.

Reliable 3D Printing Service in Hyderabad for Prototypes and Production

In Hyderabad, the use of 3D Printing for Industrial and Engineering has progressed beyond the use of 3-dimensional printing to create visual models of products. We now see engineers and manufacturers using 3-D printing to produce functional prototypes of parts created for low-volume production, as well as establishing functional applications of products from the results of these prototypes during testing in their applications.

As part of the design and prototyping process, we create parts that can be evaluated on their fitment, functionality, and overall design viability, as opposed to just visualizing them. Upon completion of the design process, the same processes control the manufacture of production-type components so that the components remain identical to each other within their respective batch sizes.

Each project we undertake begins with a project lead; we are engineers first and foremost, therefore, we develop a complete understanding of the components intended use, including load parameters, tolerances, and operational environments. Based upon this information, we select the most appropriate 3D Printing Technology (e.g. SLS, SLA, FDM, etc.) and the most suitable Material for manufacturing; thereby minimizing the amount of Rework required and delivering predictable results.

Having Local Logistics in Hyderabad gives our project Support Teams (Project Manager, Engineer, and Project Coordinator) a high degree of clarity, realistic lead-times, and easier access to all Technical Support throughout the project phases, whether the requirement is for a single Functional Prototype or for a Small Production Run. Our goal is to deliver Reliable 3D Printed Parts that function as intended when used in their intended application.

3D Paradise Provides 3D Printers in Hyderabad

Vafer Dual Extruder 3D Printer

A professional dual-extruder FDM 3D printer built for multi-material printing, ideal for engineers and R&D teams to create complex functional prototypes with minimal post-processing.

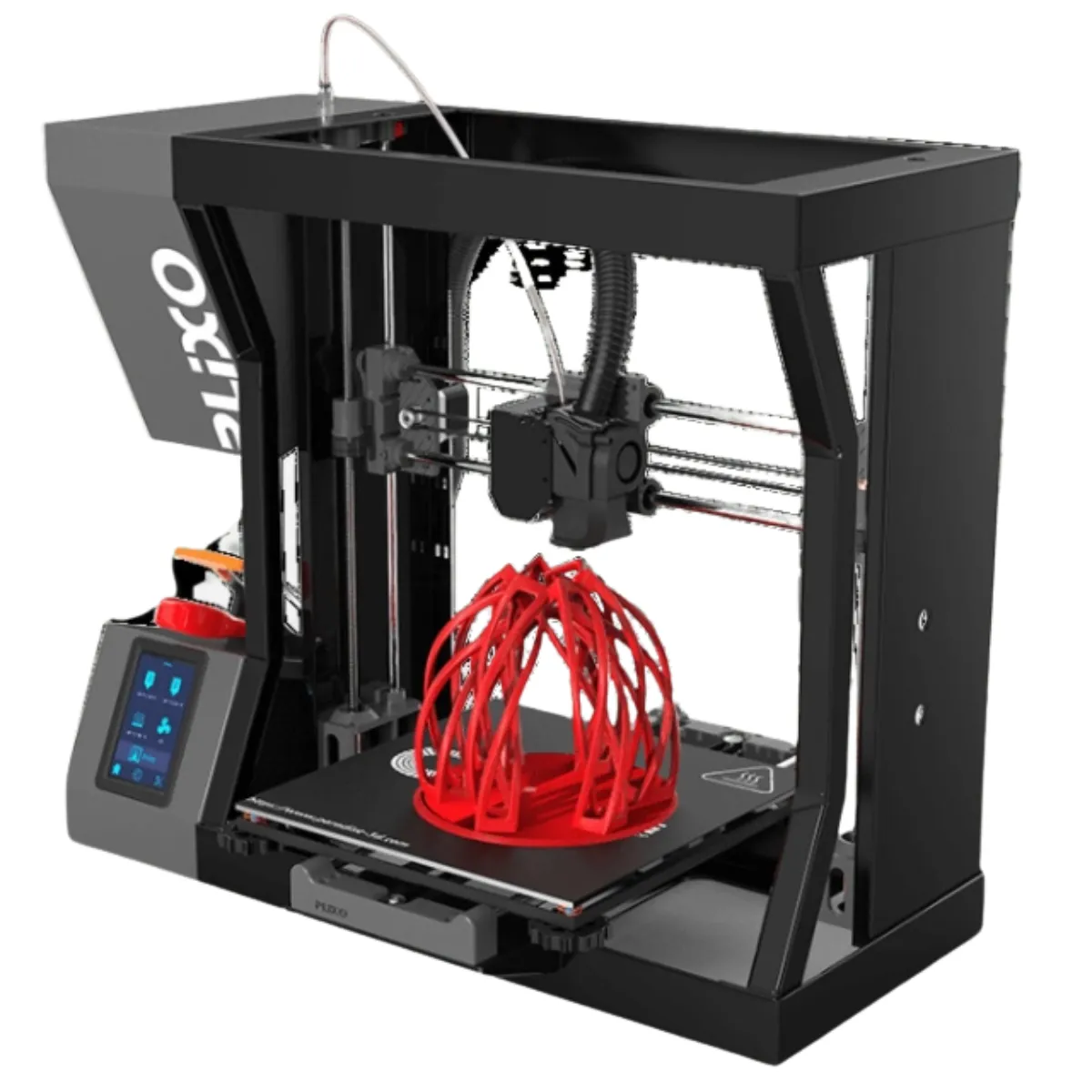

Plixo 3D Printer

Plixo 3D Printer is a stable, affordable single-extruder FDM printer ideal for education and daily prototyping, featuring a heavy metallic frame with UPS for reliable, low-complexity printing.

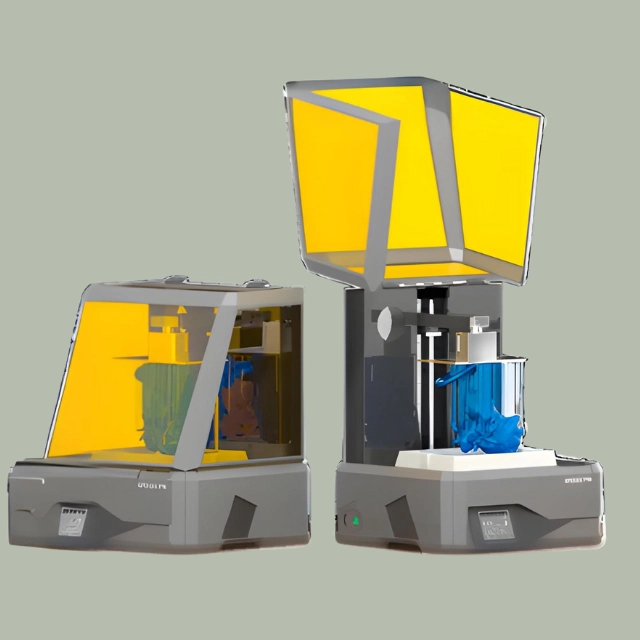

OptiCast Pro 3D Printer

A high-resolution 4K DLP resin 3D printer designed for jewelry and dental applications, delivering distortion-free precision and production-grade surface finish for professionals.

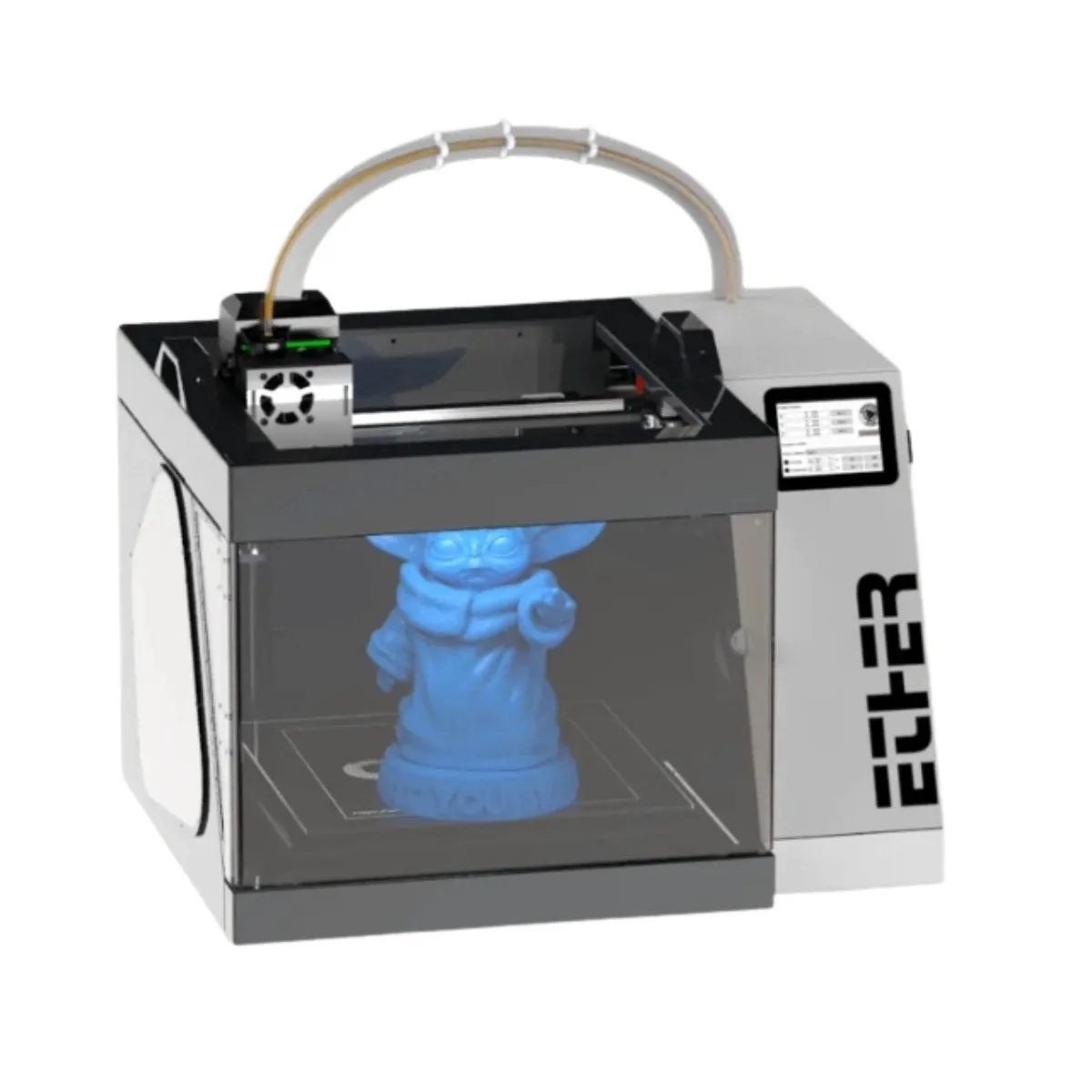

Ether 3D Printer

A reliability-focused FDM 3D printer built for moisture-sensitive filaments, featuring a real-time filament dryer to reduce print failures in office and lab environments.

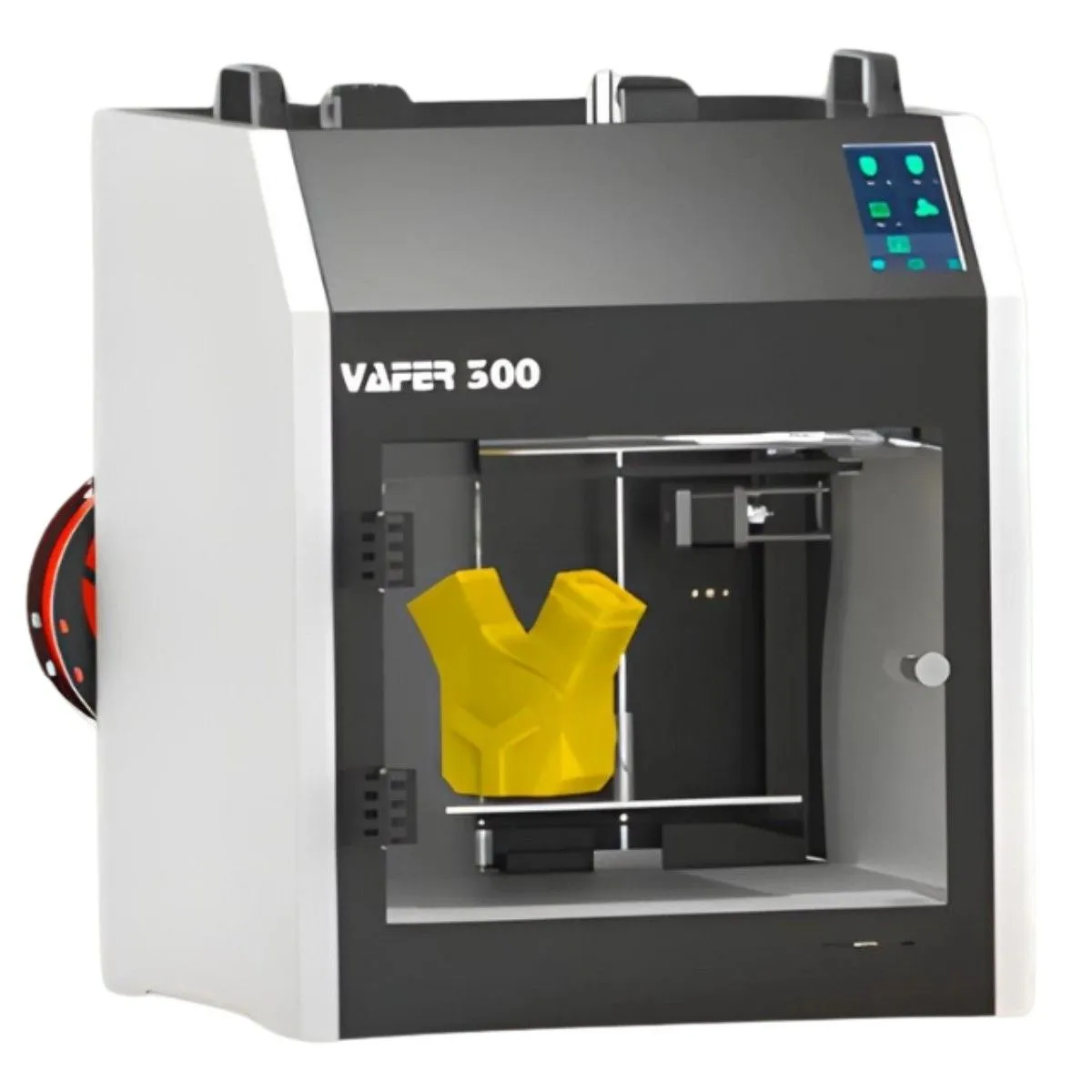

Vafer 500 Independent Dual Extruder

An industrial-grade IDEX 3D printer designed for high-temperature materials, featuring a heated chamber that enables scalable, reliable production for manufacturing and R&D applications.

Plixo XL 3D Printer

A large-format FDM 3D printer built for industrial users, offering a 500×500×500 mm build volume to produce large prototypes without part splitting.

EtherSP 3D Printer

A high-speed industrial 3D printer engineered for fast production, delivering up to 300 mm/s print speeds to help production teams significantly reduce lead times.

Resin 3D Printers

A concise resin 3D printer buyer guide designed for high-detail printing, helping precision-focused buyers make faster, more confident purchasing decisions.

3D Printer Filament

A comprehensive filament material guide that helps all FDM users choose the right materials by understanding strength and surface finish, ensuring better print reliability.

Advanced 3D Printing Technologies Available

This type of printing is intended for producing large parts and for creating cost effective tooling.

-Maximum size of a single Build area: 100 cm x 100 cm x 100 cm

-Material Types Used: ABS, PETG, Nylon, and Carbon Fiber Filled Polymers.

-Use Cases: Jigs, Fixtures, Architectural Models.

This is used when the requirement of high detail/finishes is important for the product being printed.

-Resolution: 25-100 microns/ materials used

-Material Type: Biocompatible/castable/engineering resins.

-Use Cases: Surgical guides, Dental Models, Casting Patterns.

Most suitable for creating functional prototypes and end products.

-Size of build area: 340 x 340 x 600 mm

-Material types: Nylon PA12, Glass-Filled Nylon, TPU

-Dimensional Stability: +/- .1 mm

-Use Cases: Covers, Automotive components and Assemblies, Drone Parts.

3D Design Services (CAD Modeling)

These technologies utilize high accuracy scanners to check parts and recreate them as needed.

-Equipment needed: GOM ATOS Q 12M Blue Light scanner

-Accuracy: Up to .01 mm

-Use Cases: Reproducing Legacy Parts, quality checking products, Creating CAD Drawings.

Funfact

Our 3D Printing Facility in Hyderabad

Hyderabad Companies Served

On-Time Delivery Rate

Client Savings vs Tooling

Customer Support

📍 Location: 3D Paradise, T-HUB in Hyderabad

🕒 Working Hours: Monday to Saturday, 24-hour operations

🎓 Startup Support: Special pricing for T-HUB startups and academic institutions

Our 5,000 sq. ft. facility houses advanced additive manufacturing systems and post-processing infrastructure, supporting clients across Hyderabad and Telangana with rapid, reliable production.

Industries We Work With

- • Engineering and R&D teams

- • Medical device manufacturers

- • Automotive and aerospace suppliers

- • Architecture and construction firms

- • Product startups from HITEC City to Kondapur

Why Choose 3D Paradise in Hyderabad

The Stages of 3D Printing

Upload your 3D model and get an instant quote. We support STL, OBJ, STEP, 3MF, IGES, SolidWorks, and Fusion 360 files.

Delivery/Pick Up

Delivery anywhere in Hyderabad area or an option to pick up from Gachibowli location.

Upload/Review

Share CAD file or requirement. Cad Engineers will review within 2 working hours.

Technology & Price Confirmation

We will assign the most appropriate process/material to manufacture your parts, together with a full quotation for cost confirmation.

Production/Quality

All parts will be manufactured and inspected at T-Hub Facility.

Ready to Get Started?

What Our Clients Say

Rated ★★★★★ on Google by 80+ happy customers for our quality, service, and reliability.

EXCELLENTTrustindex verifies that the original source of the review is Google. Helped us design and manufacture a new product. Supportive staff and high quality services.Trustindex verifies that the original source of the review is Google. NiceTrustindex verifies that the original source of the review is Google. 2 year'sTrustindex verifies that the original source of the review is Google. Unser Unternehmen in Deutschland wandte sich an 3D Paradise für die Entwicklung neuer Produkte und kundenspezifischer Lösungen für den europäischen Markt. Das Unternehmen 3D Paradise mit Sitz in Delhi setzte unsere Ideen und Konzepte in ergonomisches 3D-Cad-Design um und realisierte einen Prototyp für uns, der jetzt ein hervorragendes Produkt auf dem europäischen Markt ist. 3D Paradise bietet wirklich schnelle, kosteneffiziente und qualitative Lösungen für Ihre Ideen und Designs. Dieses Unternehmen hat die Kompetenz, Ihre Probleme zu lösen und Ihre Konzepte und Ideen in reale Produkte umzusetzen. Wir sind sehr zufrieden mit dem Engagement von 3D Paradise und streben eine lange, fruchtbare Geschäftsbeziehung an.

Common Questions

FAQ'S

3D printing cost will depend on 3 things - part geometry, material, and the type of printing technology you use. You will receive final pricing after reviewing the CAD file. As a rough guide: FDM is the least expensive technique; SLA and SLS are typically 2–3x more than FDM; and DLP is usually 2–4x more expensive, depending on the application.

If your file is approved by 11 AM, you can have small parts (80 × 80 × 80 mm) printed in the same day using either FDM or DLP. SLA work will typically take 1-3 days, while SLS parts will take 3-5 days to complete.

There is no minimum order quantity for FDM and SLA prints; you can order just 1 part. For SLS and DLP prints, there is a minimum order value of ₹1,000 because of the setup cost associated with the process.

Absolutely. Our professional 3D scanning services provide you with the completed CAD output in the STEP, IGES, or XT format, making them ready for manufacturing or redesign.

We accept 3D printing files in STL, STEP, IGES, and XT formats. Of all these formats, STL is the most commonly-used 3D printing file format, allowing for faster processing times.

For the most part, we complete most of our 3D printing jobs within 24-72 hours depending on the size of the item, type of material, and which technology was used to print each item. In cases of urgency, we can prioritise your job for a quicker turnaround.

We offer several types of materials for 3D printing in Hyderabad, including PLA, ABS, Nylon PA12, TPU, engineering plastics, and a range of resins. The choice of material is based on the requirements of your application (e.g., prototype, functional testing, or end-use component).

Yes. Before we print any product, our engineers complete a manufacturability and design review of all printed files to minimise any issues during the printing process.

Clients We Serve